Power Washing Service Software for QuickBooks™

Manage your business with the leading power washing service software and mobile solution that seamlessly integrates with QuickBooks™

Efficiently Manage your Pressure washing business & Maintenance Needs with The Service Program.

With its compatibility with mobile devices such as iPhones and Android phones, and its many functional features, The Service Program is the optimal software solution to manage general delivery routes and services. Especially when it’s also one of the most affordable solutions on the market.

Eliminate double entry. Post invoices, employee time, bills, etc.

Optimize routes by area, day and tech.

Optimized routes = Increased Profitability

Enter work orders from desktop or in the field. Set up recurring tasks.

Track profitability, material costs of parts used, improve communications between all staff.

We can also digitize your forms and documents.

Pressure Washing Management Software Features & Benefits

The Service Program allows you to manage tasks and help you record, track, manage and report to your residential and commercial pressure cleaning business customers:

Document Important Details.

Maintain a record of type of service including; equipment checks, maintenance and repairs, etc. Track parts and inventory usage from multiple locations. Keep track of time onsite.

Scan and track equipment with affordable, easy bar coding labels. Take before and after pictures of jobs. Track materials used to help manage costs.

Streamline Scheduling & Dispatching.

Manage job scheduling and dispatching in real-time. From the built in scheduler the drag and drop feature allows you to assign a task to a specific employee or route and updates will appear on the employees route schedule on the mobile device. Easily schedule one time and recurring jobs.

Quote & Bill Efficiently.

Generate invoices in the field that seamlessly post to QuickBooks.

- Quote jobs in the field and capture electronic signatures

- Set reminders to follow-up on quoted/completed jobs

- Print invoices right out of QuickBooks™

- Bill on any billing cycle in advance or arrears

- Bill for hours of use

- Bill on any frequency: by day, week or month & prorate returns

The Mobile Solution.

This option allows your techs to know when, where and what needs top be serviced while being both paperless and efficient while in the field.

- Scan QR Codes on equipment

- Create and complete repair orders

- Receive payments in the field

- Google Web Mapping

- Enter bills from parts warehouse and into QuickBooks™

- Schedule and complete PMs & much more!

Get Organized

- Track job profitability

- Improve staff communications

- Quickly know if a something gets missed

- Track onsite time for employees and material costs of parts used

Seamless QuickBooks™ Integration

- Seamlessly integrates with QuickBooks Desktop & Online

- Post invoices, employee time, bills, etc.

- Works with classes and sales reps

- Eliminates double entry!

Route Management

- General delivery crew tracking

- Stop verification

- Optimize routes by area, day and tech

- Track when driver arrives/departs (requires mobile)

- Take pictures once a stop has been serviced

- GPS pinpoint vehicle upon arrival/departure (requires mobile)

- Map to each stop or service call while on the road

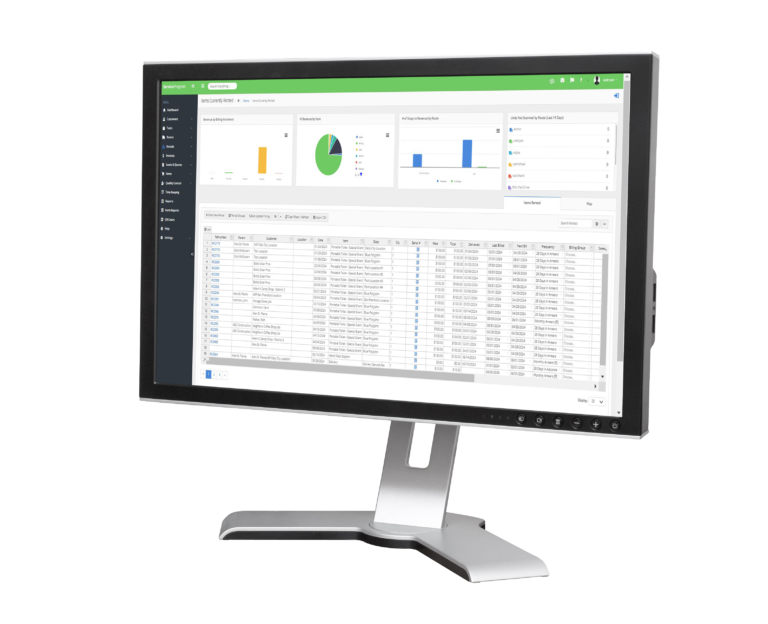

click to view larger image

Improved Field Communications

- Enter/complete tasks and work orders

- Take pictures of service requested before and after completion

- Enter/view customer equipment

- Signature capture, print and/or email transactions

Service Department Management

- Enter work orders on desktop or in the field

- Quickly know if something gets missed

- Set up recurring tasks like annual maintenance

click to view larger image

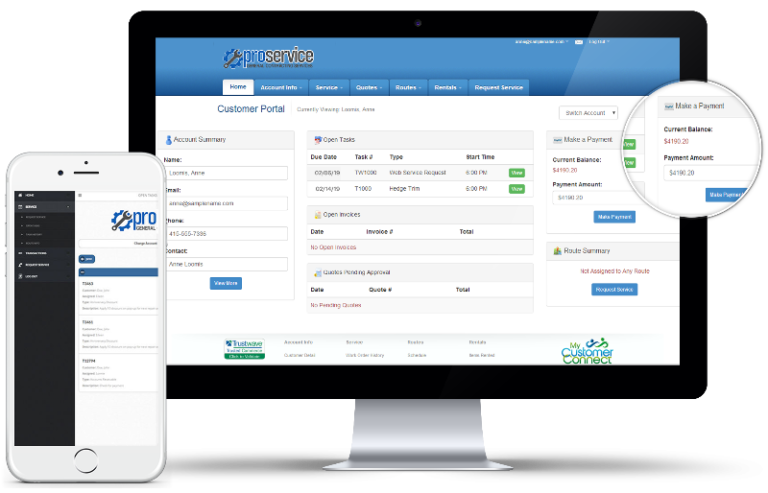

click to view larger image

Customer Portal & App

- Your customers simply download the app on their iOS or Android devices and connect with your business ANYTIME, ANYWHERE!

- Customers can enter work orders (with images) of service issues

- View QuickBooks™ invoice and payment history

- Online Store

- Bill Pay

- Accept quotes and electronically capture signatures

Equipment Tracking

- Enter and view equipment in the field

- Track repair history on equipment

- Create custom lists based on types of equipment

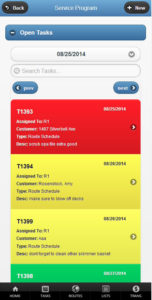

Take a closer look at The Service Program Mobile Solution

Mobile software that's compatible with your QuickBooks desktop and QuickBooks online.

click image to view larger

click image to view larger

click image to view larger

click image to view larger

Helpful Video Demonstrations

Step-by-step videos about how The Service Program can help grow your business.

Schedule View Calendar

Work Order Tracking

Checklists & Crew Time Tracking

Enter Bills/Job Costing

Working On The Mobile

Posting Into QuickBooks™

What are you waiting for? Order The Service Program today!

Increase the communication within your company. Deploy mobile devices. Route more efficiently. Schedule work orders and service calls.